ESD Protected Separators

Intelligent Protection for Electronic Components

Electrostatic shock can damage, erase or alter sensitive electronic components. It can cause magnetic atmospheres and even explosions.

To minimize the risk, conductive, anti-static or static dissipative plastic materials should be used. ESD protected materials must be used to protect electronic products against electrostatic shock. With ESD protected products, static electricity charge is discharged in a controlled manner. The surface resistance of ESD protected materials varies between 10^6 ohms and 10^9 ohms. In ESD protected separators, the risk of electrostatic charge is extremely low and they are safe against electrostatic discharge. Materials with ideal ESD protection should have values between 10^6 ohms and 10^9 ohms. Values outside this range leave electronic components unprotected. As Uluform, we offer the most suitable ESD protected solutions for all your electronic components.

Difference Between Distributor and Conductor

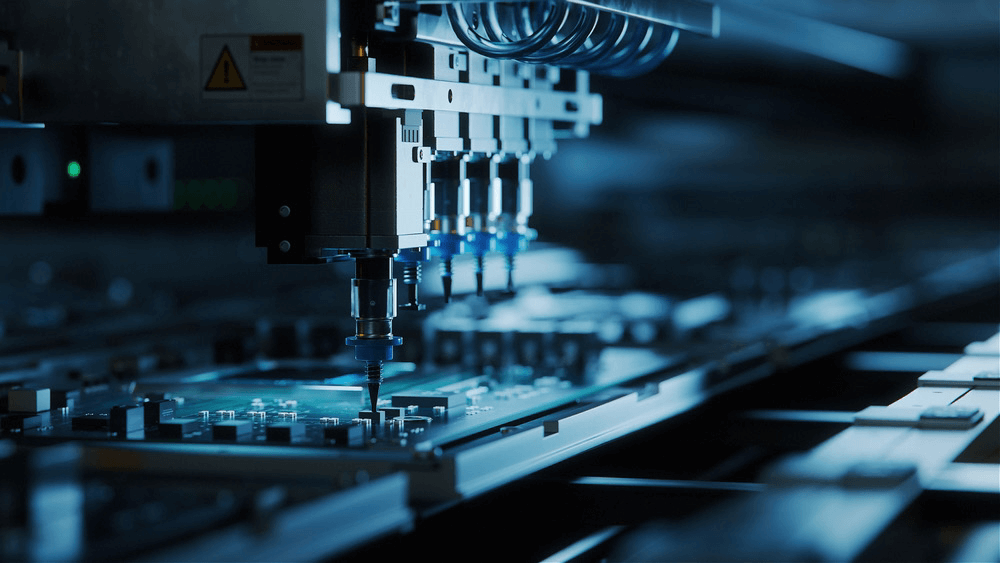

Electricity at rest is static electricity. Electrostatic voltage occurs as a result of the transfer of electrons, sliding, friction or separation of the material. Exposure to electrostatic voltage results in a mild or painful shock. If this happens to electronic components, the electronic product is exposed to electrostatic discharge. In this case, products are often damaged even at low voltage. The main cause of electrostatic electricity is usually employees.

During assembly or transportation of electronic devices ESD protected products must be used. If unsuitable carrier containers are used, electronic components will still be at risk depending on the materials used.